Different Thinking for the seam welding

1. The reason of various welding process for the seam welding

- During the welding, there is huge amounts of heat generated at the seam.

- So, Have to find out to protect the flux inside.

- Below, different method to weld the seam for seamless FCW.

2. Different Welding Methods

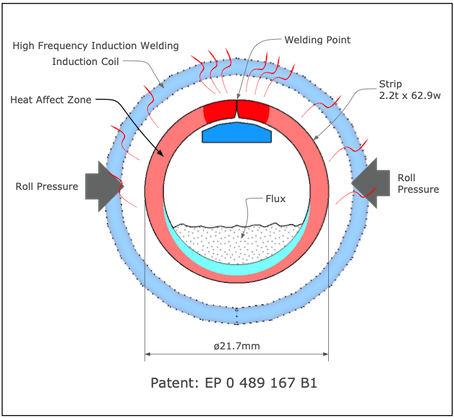

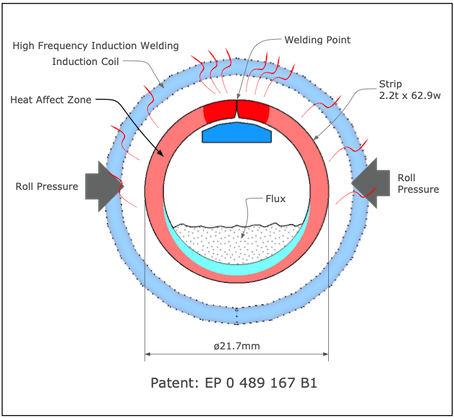

2-1 Old Method according to the patent of EP 0489167 B1

- Old patent that the laser welding has not yet introduced the the seam welding.

- Lots of heat generated from welding point enough to burn all surface of tube.

- To protect the flux, it need to secure some distance from heat source.

- Big tube make the manufacturing process complicate.

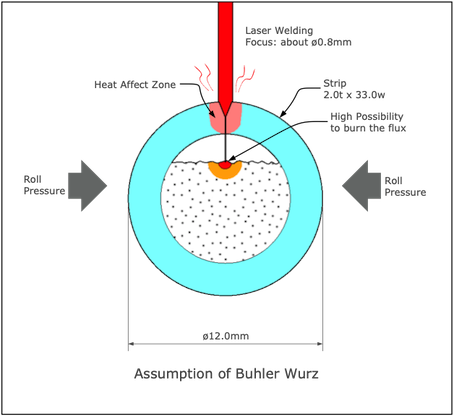

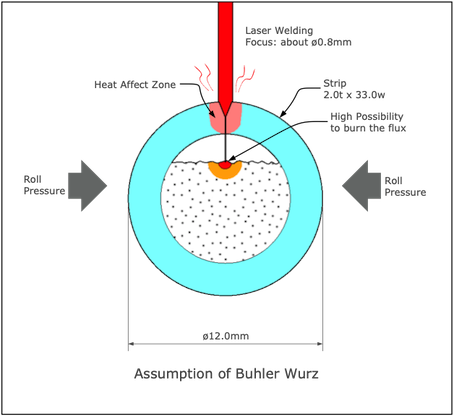

2-2 Assumption of Bühler (PPT data)

- Up to date technology to make a seamless FCW from Europe.

- However still big tube to make the seam welding that make the process complicate.

- Also has small possibility to burn the flux since laser light can penetrate extremely small gap of the seam.

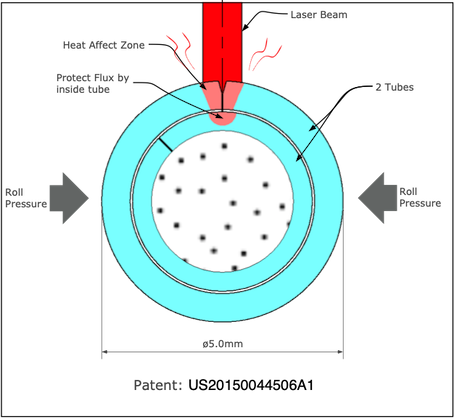

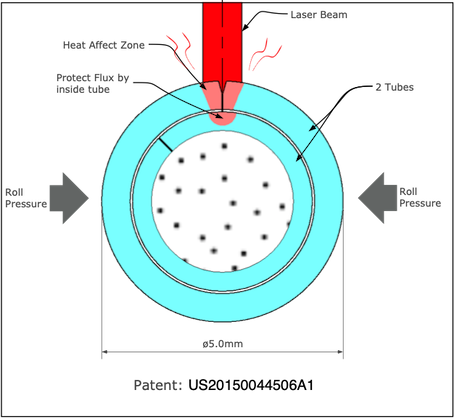

2-3 Double tube method from the Patent of US20150044506A1.

- To protect the flux, add one more tube to weld.

- Cause of the small tube diameter similar to the existing process, very simple to make a final products

- However some cumbersome works needed for double tube and some obstacles to adjust fill percent of flux

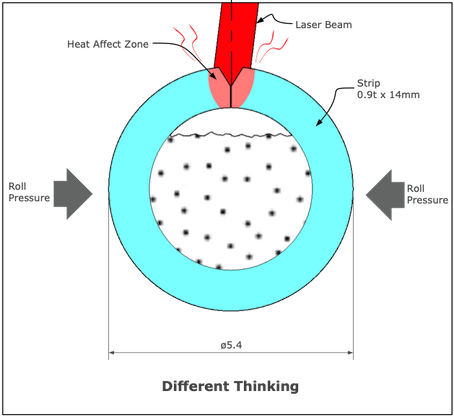

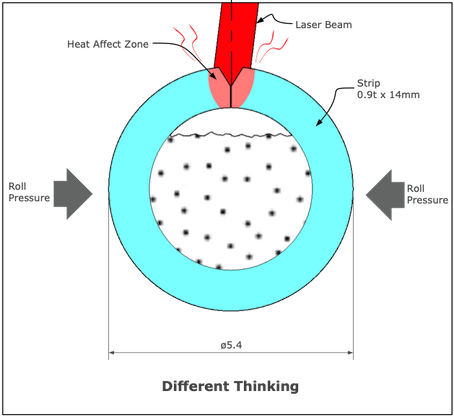

3. Different Thinking for Welding Seam.

- Not to penetrate the laser beam to the flux, adjust the angle of laser.

- Or make the tube type of folded so the beam could not reach to the flux

- Could realize the simplest welding for seamless FCW.

author:Alex Kwak

© copyright reserved.

I do not take any responsibility except on Contracts. alexkwak24@gmail.com